Drying Room For Sale

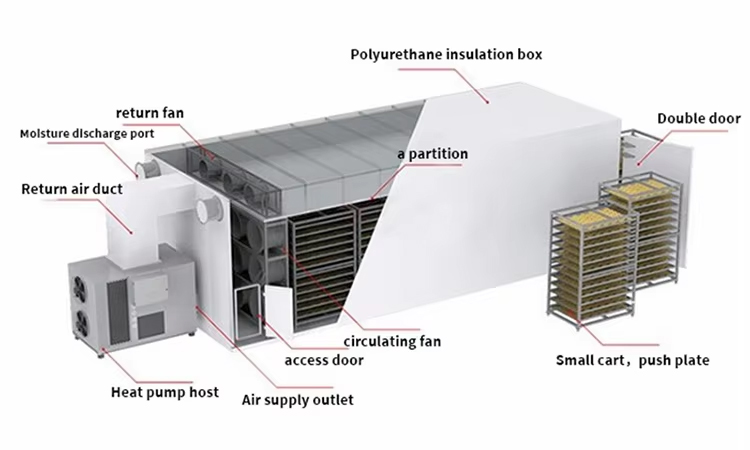

Drying Room Introduction

Electric heating drying room is an environmentally friendly and energy-saving drying equipment that uses clean hot air heating, simple and practical air supply and distribution, greatly improving drying efficiency and reducing energy consumption.

The entire drying process does not produce any harmful substances, nor does it produce smoke or open flames. It can also adjust the temperature and humidity according to the characteristics of the dry material. High degree of intelligence, no need for dedicated personnel to supervise the drying process. After reaching the drying temperature of the material, the unit will automatically stop to achieve energy-saving effect.

The finished products dried in the drying room have the advantages of cleanliness, smoothness, and no peeling. The size of the drying room can be customized according to user requirements. The size of the drying room can be customized according to user requirements.

Drying Room Working Principle

The working principle of an electric heating dryer is to generate heat through electric heating elements, heat the air, and then blow the heated air onto the material or item to be dried through a fan or airflow system. Hot air absorbs moisture from the surface of an object and carries it away through evaporation, thereby achieving the effect of drying. By controlling parameters such as temperature, humidity, and wind speed, the drying process of materials can be effectively accelerated.

Drying Room Advantages

- Clean and hygienic:The design of a closed drying room does not come into contact with the outside air, ensuring the quality of drying materials.

- Drying evenly:The drying room is equipped with multiple circulating fans to ensure uniform air flow and temperature, and uniform drying effect for the same batch of materials.

- Intelligent temperature control:Not subject to weather marketing, able to operate stably 24/7.

- High thermal efficiency, by driving the compressor to do work to achieve the transfer of heat, one degree of electricity can be used as three degrees of electricity temperature -75° C;

- Low carbon environmental protection, fog emission;

- The electric auxiliary heat is sufficient and can be heated rapidly

Drying Room Application

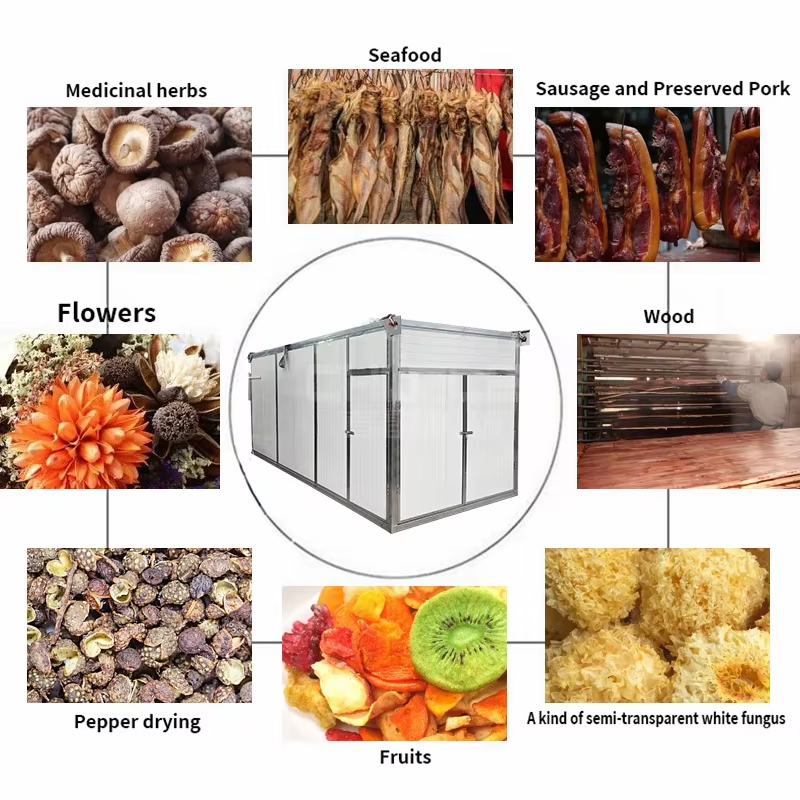

Suitable for multiple materials:

【Applicable industries】Its wide applicability makes the hot air circulation drying room widely used in multiple industries such as food processing, pharmaceuticals, and chemicals.

【Scope of application】Suitable for drying dehydrated vegetables, fruits, flower tea, grains, meat, medicinal materials, health products, agricultural and sideline products, chemical raw materials, pesticides, feed and other materials.

Drying Room Technical Parameters

| Model number | HHK1000 | HHK2000A | HHK2000B | HHK3300 |

| Structural form | box-type | |||

| Dimension(mm) | 5000×2200×2175 | 5000×4200×2175 | 6600×3000×2175 | 7500×4200×2175 |

| Fan power | 0.55KW×6 | 0.55KW×12 | 0.55KW×12 | 0.75KW×12 |

| Temperature range | Normal temperature-75℃ | |||

| Carrying capacity | 1000-2000kg | 2000-4000kg | 2000-4000kg | 3300-7000kg |

| Drying volume | 20m³ | 40m³ | 40m³ | 60m³ |

| Can accommodate the number of dryer(set) | 6 | 12 | 12 | 20 |

| Stack car size | 1200×900×1720mm | |||

| Trailer material | Stainless steel/Galvanized | |||

| Accessory area | 97.2㎡ | 194.4㎡ | 194.4㎡ | 324㎡ |

| Host type | KL2-7 | KL2-15A | KL2-15B | KL3-25 |

| Main engine power | 7P+12KW+3.4KW | 15P+24KW+6.7KW | 15P+24KW+6.7KW | 25P+36KW+10KW |

| Voltage | 380V 3N | |||

| Control system | PLC+7 inch touch screen | |||

RECOMMENDED PRODUCTS

loading…

已经是到最后一篇内容了!

Chunlei Rotary kiln

Chunlei Rotary kiln