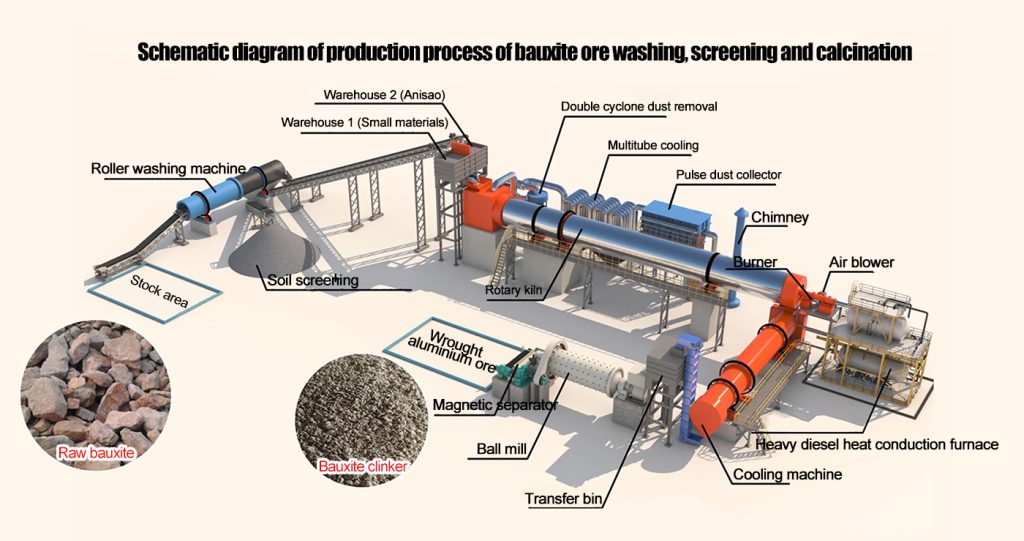

Bauxite Rotary Kiln For Sale

RECOMMENDED PRODUCTS

- View details

Ball Mill

Ball mill, also known as grinding mill, is an important equipment in the grinding process, mainly placed after the crushing equipment, is the key equipment for coarse gravel material crushing again. Including cement mill, raw ma…

- View details

Jaw Crusher

There are two styles of Chunlei Machinery Jaw Crusher, one is PE/PEV Jaw Crusher and the other is CJ European Jaw Crusher. PE/PEX Jaw Crusher is used for coarse, medium and fine crushing of various ores. It can be made into …

- View details

Pulse Dust Collector

DMC series single machine pulse dust collector adopts the cleaning method of pulse jet, which has the characteristics of high cleaning efficiency, proper air volume, long filter bag life, small maintenance workload, safe and rel…

- View details

Belt Conveyor

Belt conveyors are designed to move bulk, homogeneous, sheet goods in a horizontal or inclined direction. They are mainly used in quarries for mining, processing and transporting ores and non-metallic building materials, in foun…

loading…

已经是到最后一篇内容了!

Chunlei Rotary kiln

Chunlei Rotary kiln