Introduction

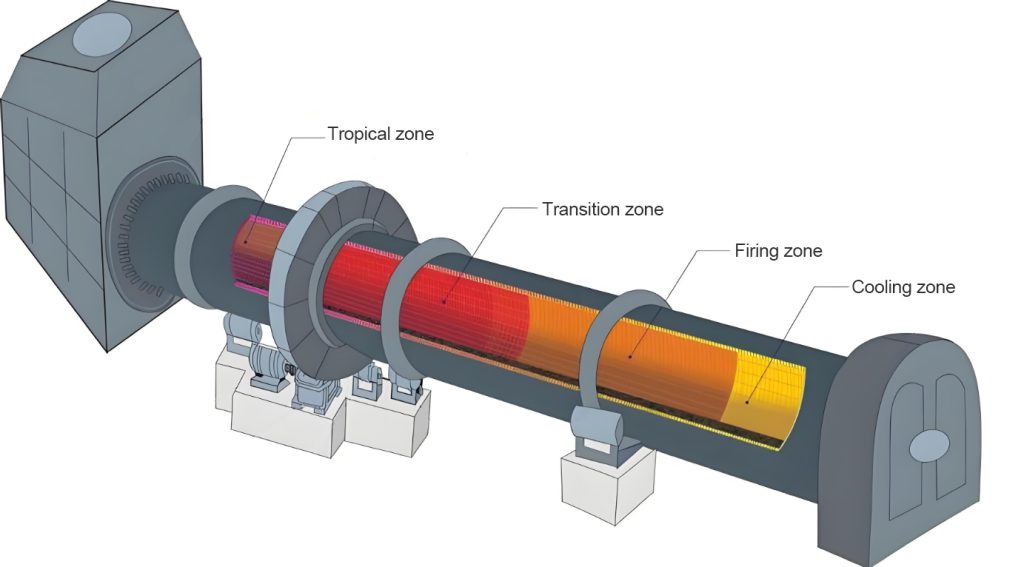

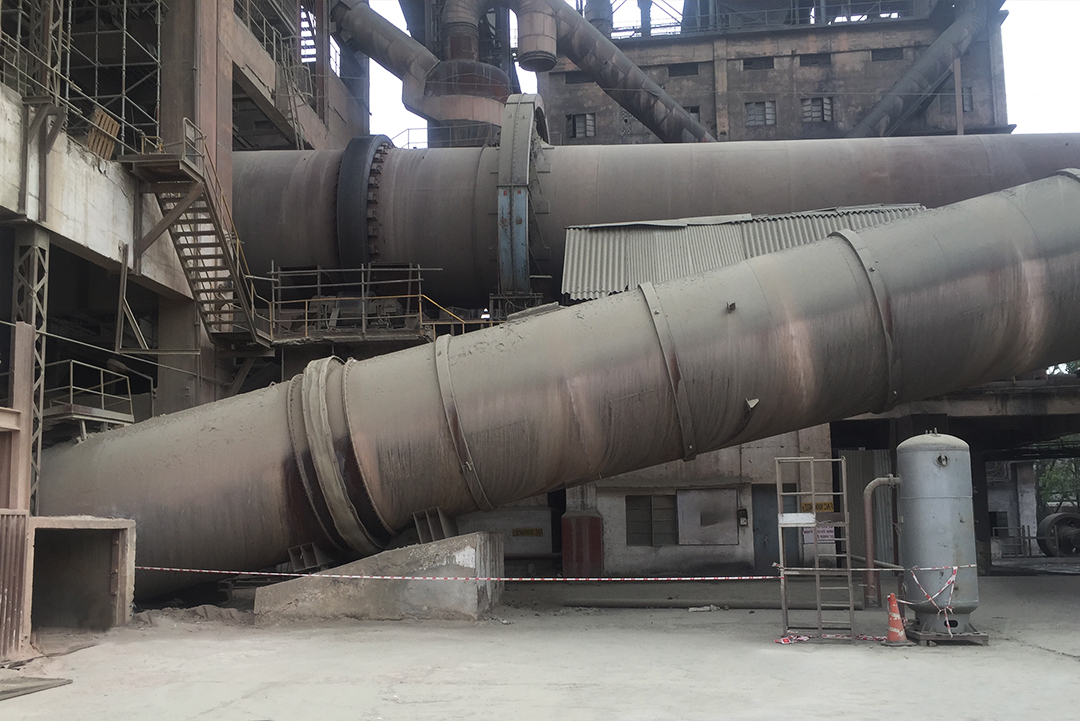

Limestone calcining rotary kiln furnace is a specialized equipment for calcining limestone, which is characterized by high efficiency, environmental protection and energy saving. Lime kiln rotary kiln as an important lime production equipment, the normal operation of the lime kiln is very important to ensure the stability and efficiency of lime production. However, the rotary kiln produces a large amount of flue gas during the production process, which, if not effectively controlled, will not only pollute the environment but also affect the production efficiency. Therefore, adjusting the flue gas control ratio of lime kiln rotary kiln in the production process will protect the environment and improve the production efficiency.

Clear control objectives

O₂ content: represents the combustion adequacy, generally controlled at 2%~5% (excess air coefficient 1.1~1.3).

CO content: represents incomplete combustion and needs to be minimized (usually <100 ppm).

NOx/SO₂: need to meet local emission standards, controlled by combustion optimization or end-of-pipe treatment.

Control of fuel ratio

Fuel selection: Choosing coal, natural gas, oil, etc. can reduce smoke emissions, of which natural gas combustion produces less smoke and is an environmentally friendly choice.

Control fuel ratio: Reasonable adjustment of fuel ratio makes combustion more complete and reduces smoke from incomplete combustion. This can be achieved by monitoring the fuel supply and adjusting the supply system.

Kiln temperature and negative pressure

High temperature is easy to generate NOx, local overheating needs to be avoided (control the temperature of the firing zone at 1200~1350℃). Fuel quantity can be adjusted by infrared temperature measurement or thermocouple monitoring. Negative pressure in the kiln is too large for air leakage and too small for flue gas spillage, usually maintained at -50~-100 Pa.

Flue gas recirculation

The use of waste heat recovery technology to recover and utilize the heat energy in the flue gas discharged from the rotary kiln not only reduces energy consumption, but also reduces flue gas emissions.

Chunlei Rotary kiln

Chunlei Rotary kiln