Three Drum Dryer For Sale

Three Drum Dryer Introduction

The three-cylinder dryer is mainly used for drying granular materials within a certain humidity range, such as dry mortar industry, various specifications of molding sand used in the casting industry, building materials and cement industry, small particle clay, the chemical industry is used for small particle materials that cannot afford chemical changes and are not afraid of high temperature and dust.

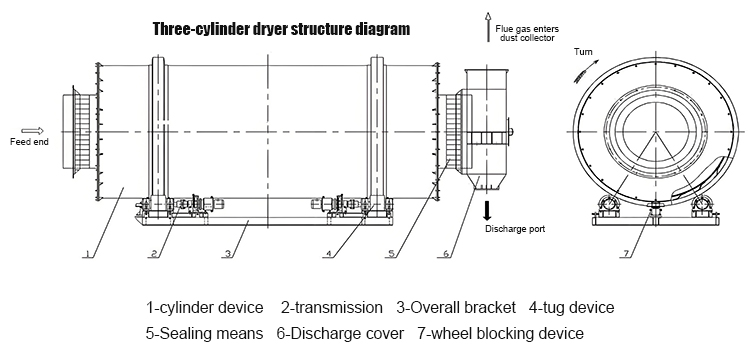

External structure and internal structure:

Three Drum Dryer Performance Characteristics

1, the structure of the three-cylinder dryer adopts sleeve type, so that the material can be dried quickly.

2, design cylinder self-insulation, so that the thermal efficiency of more than 80%.

3, the product structure is exquisite, smooth operation.

4, the drying effect is good, tons of dry coal consumption is less than 8kg.

5, the fuel can be used for kerosene gas. It can dry the bulk powder material below 20mm.

6, than the single cylinder dryer to reduce the floor area of about 50%, civil investment reduced by about 50%, power consumption reduced to 60%.

7. The final moisture index required can be easily regulated according to user requirements.

8, low gas temperature, dust removal equipment for a long time.

9, without the size of the gear rotation, the use of tugwheel rotation.

10, discharge temperature below 60 degrees. Continuous production of packaging.

Three Drum Dryer Application

Three Drum Dryer Working Principle

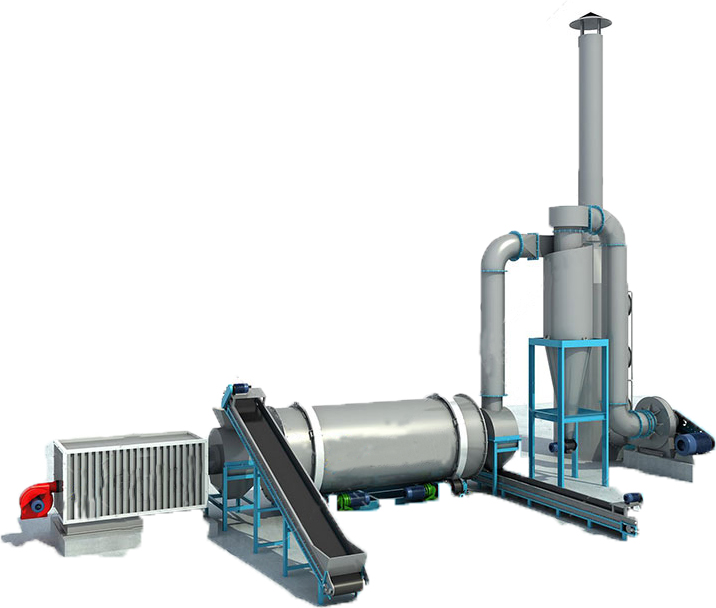

The material enters the inner layer of the three-cylinder dryer by the feeding device, the material is continuously picked up and scattered under the sheet of the inner layer to achieve heat exchange in a spiral way, and the material moves the other end of the inner layer into the middle layer for countercurrent drying. The material is constantly lifted into the middle layer repeatedly, in a way of advancing two steps and one step back. The material fully absorbs the heat emitted by the inner layer drum in the middle layer. It also absorbs the heat of the middle roller, and prolongs the drying time, and the material reaches the dry state here. Then the material falls into the outer layer from the other end of the middle layer, and the material travels in a rectangular multi-loop mode in the outer cylinder, and the material that achieves the drying effect travels quickly out of the cylinder under the action of hot air. The wet material that does not achieve the drying effect cannot travel quickly due to its own weight, and the material is fully dried in the rectangular sheet, thus achieving the purpose of drying.

Three Drum Dryer Technical Parameters

| Mode(m) | Ф2×4.5 | Ф2.2×5 | Ф2.5×6 | Ф2.7×6.5 | Ф3.0×6.5 | Ф3.2×7 | Ф3.6×8 | Ф4.2×8 |

| Outer tube diameter(m) | 2 | 2.2 | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 | 4.2 |

| Length of outer tube(m) | 4.5 | 5 | 6 | 6.5 | 6.5 | 7 | 8 | 8 |

| Cylinder volume(m3) | 14.13 | 18.99 | 29.43 | 37.19 | 45.92 | 56.27 | 81.39 | 110.78 |

| Cylinder speed(r/min) | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 |

| The maximum intake air temperature(℃) | 700-750 | 700-750 | 700-750 | 700-750 | 700-750 | 700-750 | 700-750 | 700-750 |

| Capacity(T/h) | 13-18 | 15-23 | 20-28 | 24-33 | 35-40 | 40-60 | 55-75 | 70-120 |

| Motor power(kw) | 5.5×2 | 7.5×2 | 5.5×4 | 7.5×4 | 11×4 | 15×4 | 18.5×4 | 22×4 |

RECOMMENDED PRODUCTS

loading…

已经是到最后一篇内容了!

Chunlei Rotary kiln

Chunlei Rotary kiln