Rotary Dryer Introduction

Dryer is mainly used to dry materials, at present, there are many kinds of dryer, dryer heat source from the combustion device, in the process of operation, its heating method is the flow heating.

Performance characteristics

1, the drying strength is large, because the material is highly dispersed in the air flow, the total surface area of the particles is extremely dry effective area.

2, the drying time is short, the airflow dryer has a simple structure, a small footprint, and is easy to build and maintain.

3, large capacity, high thermal efficiency. When drying unbound water, the thermal efficiency can reach 60%.

4. The dryer realizes “zero horizontal thrust”, greatly reducing the wear of the retaining wheel, and the cylinder runs smoothly and reliably.

5, the dryer adopts the “aligning wheel support device”, so that the support wheel and the rolling ring are always in linear contact, thus greatly reducing wear and power loss.

The different inner structures are shown as below:

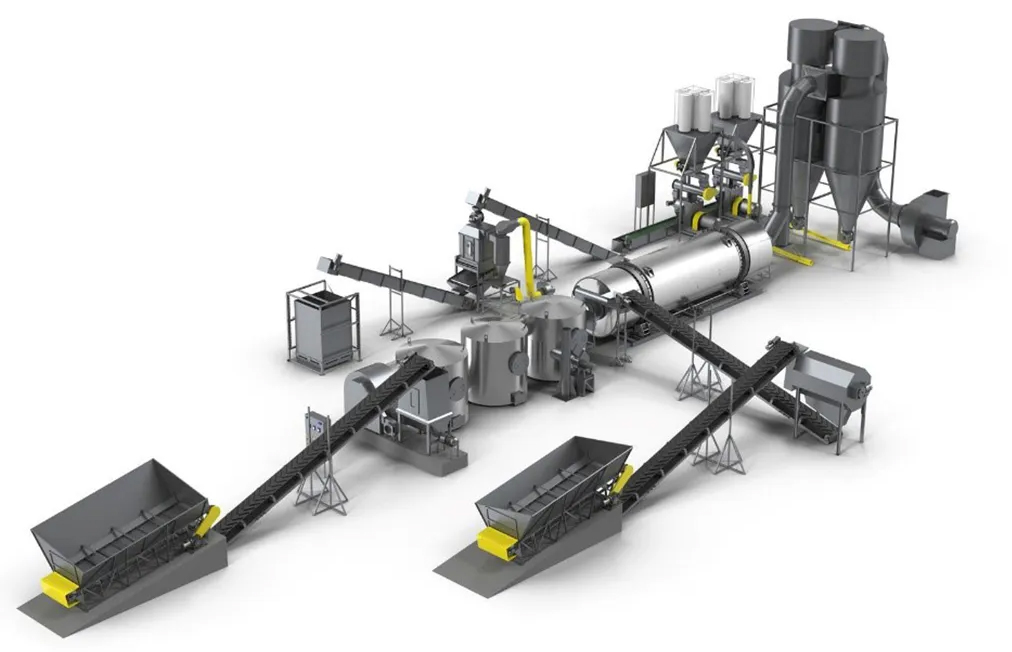

Process flow chart is as follows:

Rotary Dryer Working Principle

The material is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feed end through the feed pipe by the feed machine of the hopper. The slope of the feeding pipe should be greater than the natural inclination of the material, so that the material can flow smoothly into the dryer. The dryer cylinder is a rotating cylinder that is slightly inclined to the horizontal line. The material is added from the higher end, the heat carrier enters from the lower end, and the material is in countercurrent contact, and the heat carrier and the material flow into the cylinder together. As the cylinder rotates the material is moved by gravity to the bottom end. In the process of moving the wet material forward in the cylinder body, the heat transfer of the heat carrier is directly or indirectly obtained, so that the wet material can be dried, and then sent out by the belt machine or screw conveyor at the discharge end. The dryer cylinder body wall is equipped with a copy plate, its role is to copy the material and scatter it, so that the contact surface between the material and the air flow increases, in order to improve the drying rate and promote the material forward. Heat carrier is generally divided into hot air, flue gas and so on. After the heat carrier passes through the dryer, the cyclone dust collector is generally required to capture the material in the gas. If it is necessary to further reduce the dust content of the tail gas, it should also be discharged after a bag dust collector or a wet dust collector.

Chunlei Rotary kiln

Chunlei Rotary kiln